Factories in a fast-paced and competitive world like manufacturing face a constant struggle with optimizing efficiency, keeping safety, and delivering the message across the entire workforce. Traditionally, factory signage came on posters, printed material, or even on simple boards. All these have been the standard solution for passing important messages over time. However, with the continuous evolution of technology, it is more than obvious that digital screens are a far better substitute. Why replacing your factory signage with digital screens is not just a trend but a wise business decision.

1. Enhanced Communication

One of the most significant advantages of digital screen within the context of a factory is that it is a powerful tool for conveying information and which can be done in real-time. The conventional signages are constrained by time when it comes to printing and distributing new materials. This can result in presenting stale information which is quite undesirable especially in environments that are as dynamic as a factory.

Digital screens can be easily updated and therefore all the workers are able to get the most recent information. From shift changes, production schedule changes, safety notifications, and any other information that needs to be conveyed to the employees, digital signage comes in handy. Furthermore, the use of digital screens is that information can be displayed in different forms such as text, images and videos, which makes it easier for the employees to comprehend and retain the information being passed across.

2. Increased Safety

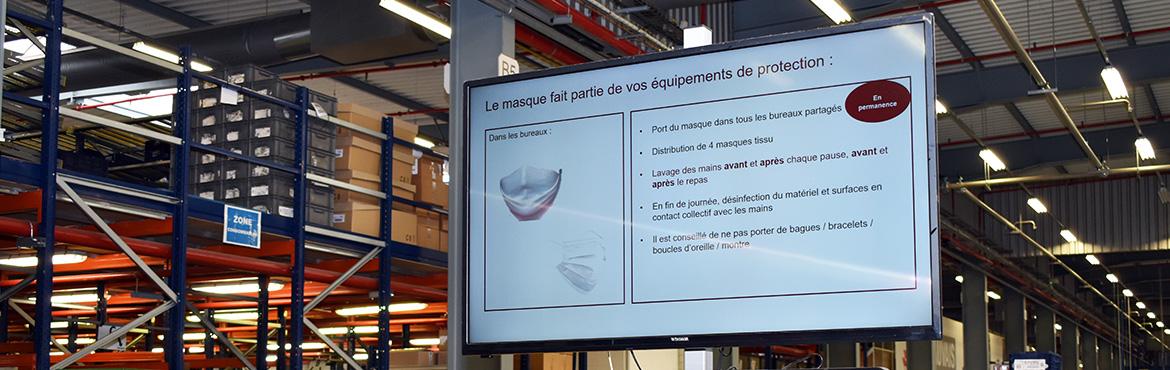

It is important to have safe working environment in any factory. It is therefore important that workers are always reminded of the risks that they are exposed to as well as the safety measures to be taken. The conventional safety signs are static and are capable of being ignored after a while due to their repetitiveness. In the course of time, employees may begin to ignore these signs and thus become less effective.

While digital screens can be set to show different safety messages at regular intervals and thus are more effective and interesting. For instance, you can post safety messages at different times of the day, post the current safety statistics or show the current status of safety risks in the workplace. This is also beneficial for the use of video content on digital screens to show safety training videos or how to use PPEs or what to do in case of an emergency.

3. Flexibility and Customization

Digital signage is one of the most effective ways of communication as it has high flexibility in content management. In the case of traditional signage, to change the information, one has to print new materials which is both time-consuming and expensive. Digital screens, on the other hand, can be changed within a short time and the process only requires a few clicks of the mouse. This makes it easier to tailor the information presented to the needs of different departments or shifts and therefore be more effective.

For instance, you can define the content to be updated at particular intervals, during shifts or at certain occurrences. This makes the information to be up to date for the current audience. Also, it is possible to present various information on the screens, for instance, production goals and results, employees’ performance indicators, motivational messages, and company news, among others, depending on the audience.

4. Cost-Effective in the Long Run

Although the initial capital investment in digital screens may be expensive than that of the traditional forms of signs, the overall costs in the future are much lower. Traditional signage needs to be printed, distributed and replaced from time to time, especially in environments that are constantly changing. These costs are cumulative and do not include the time and energy that is required to keep the physical signs up to date.

As compared to traditional print media, digital screens do not require frequent reprinting, and the content can be changed at any time with no extra costs involved. In the long run, this leads to a lot of savings. Also, digital screens are not easily prone to damage and are built to last in the industrial setting and therefore do not require frequent replacement.

5. Improved Employee Engagement

Motivating employees in a manufacturing plant environment can be a daunting task due to the fact that the employees are often times working on the same task repetitively. Digital screens can be a great way of improving the morale of employees and getting them more involved. For instance, through real-time production data, you can make workers feel as if they are in a competition and thus can motivate them. Other ways to increase the motivation level of employees include rewarding the high achievers, celebrating achievements, or sharing positive feedback received from customers.

In addition, it is easier to present training material in a more engaging and interactive manner on digital screens. Rather than using boring posters or manuals, it is possible to use brief video clips or quizzes to enhance the training process as well as make it more engaging for the employees.

6. Centralized Control and Management

It is not easy to manage traditional signage across a large factory and changes have to be made on a regular basis. Digital signage systems normally have a centralized control where you can control all the screens at once. This means that content can be updated and scheduled as well as monitored in real time throughout the entire facility.

This way of managing also has the advantage of being timesaving and also makes sure that everyone gets the same message regardless of the department in the factory. This is especially the case in large organizations where different areas or divisions may require different information. In digital screens, you are able to make sure that the right message is being communicated to the right audience at the right time.

7. Environmental Impact

It is evident that sustainability is a growing concern for organizations across the globe. The conventional signage is a paper or material-based system which is not eco-friendly and causes pollution. In this way, factories can save a lot of energy and therefore reduce their impact on the environment. Digital signage does not require paper, ink and other resources that are used in conventional printing. Moreover, the majority of the current digital screens is produced with the aim of saving energy and, therefore, contribute to the preservation of the environment.

8. Future-Proofing Your Facility

In this fast changing world, industries are also changing and the tools and technologies used in industries are also changing. It is for this reason that by adopting digital signage in your facility today you are preparing for tomorrow. Digital screens are relatively simple to upgrade and can be connected with other technologies, for instance, IoT or manufacturing software, to give additional value in the future.

For instance, digital screens can be coupled with IoT sensors to show information of the performance of the machine, energy used or conditions of the environment of the factory. This not only increases communication but also assist in decision making process to increase the overall efficiency and productivity.

9. Enhanced Aesthetics and Branding

the appearance of digital signage is also of great importance, since the main function of the displays is to convey information. Digital signs can enhance the image of your factory, and that can be useful for the employees and when you have guests or business partners visiting the factory. It also provides a way to re-assert your brand’s image by including company ethos, vision and/or logos in a creative and engaging manner.

10. Scalability

It is therefore important to note that as your business expands so does the need for communication. In comparing digital signage with the traditional forms of signage, the former has the advantage of scalability. Digital signs can also be conveniently installed in new zones within the factory or new facilities and controlled through the same CMS. This scalability means that your communication infrastructure can expand with your business and there is no need for you to replace the entire system.

Conclusion

Upgrading your factory signage with digital screens is not merely about keeping pace with technological advancements; it’s a strategic decision that can significantly enhance communication, improve safety, and boost overall efficiency. Although the initial investment may be higher than that of traditional signage, the long-term benefits in terms of cost savings, employee engagement, and operational efficiency make it a sound investment. In the increasingly competitive manufacturing landscape, digital screens provide the flexibility, scalability, and future-proofing necessary to stay ahead of the competition.