The speed of data is the speed of factories. The production of Digital Signage takes that data to the shop floor, where the decisions are made. Whether it is KPIs and Andon calls, or safety notices and training loops, the correct screens, driven by manufacturing digital signage software, transform the uncoordinated and paper-based sprawling facility into a coordinated, paperless, and always up-to-date facility.

From Clipboards to Command Centers

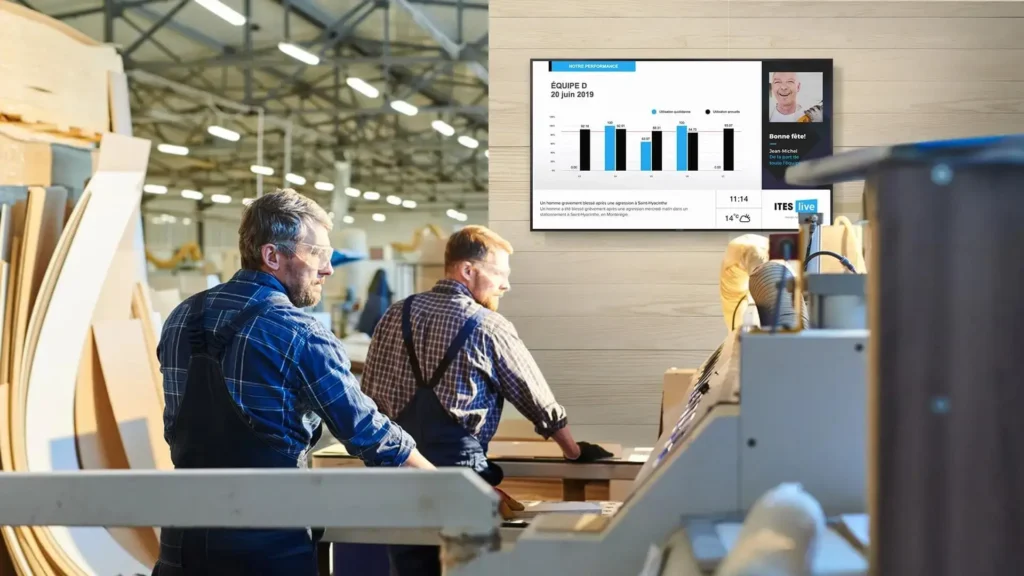

Ten years ago, the teams used printed schedules, wall calendars, and word of mouth. In the present day, Digital Signage manufacturing sends live metrics, shift goals, and alerts to each cell. That is not cosmetic evolution; that is functional evolution. When the takt time is missed or the feeder line is jammed, visual cues on Manufacturing Data Display boards help the teams to act in seconds, not hours.

What Exactly Is Manufacturing Digital Signage?

Consider Manufacturing Digital Signage as a safe content and data layer that drives monitors, video walls, and rugged kiosks throughout your plant. Your manufacturing digital signage software is the platform that connects with your ERP/MES, CMMS, quality systems, and IoT sensors, and then provides role-specific views: OEE in assembly, scrap analytics in quality, maintenance backlog in the tool crib, and standard work in training zones. It is Digital Signage for Manufacturing and Industrial settings, and it is designed to withstand noise, vibration, and 24/7 duty cycles.

Core Benefits of Digital Signage for Manufacturing

Real-Time Data Dissemination

Live takt vs. actual, OEE, changeover timers, and WIP status stream to Manufacturing Data Display boards at each station. Teams will detect bottlenecks when they happen and make adjustments before variance accumulates.

Safety Alerts & Emergency Notifications

Strobes and sirens are important–so are clear directions. Digital Signage Manufacturing distributes evacuation maps, muster points, weather warnings, lockout/tagout reminders, and near-miss notices across lines and common areas in a matter of seconds.

Streamlined Internal Communications

Handoffs of shifts, staff changes, and material calls are not based on radio chatter anymore. Supervisors send information to specific areas, and only the appropriate individual views the appropriate message at the appropriate time.

Production Efficiency You Can See

Manufacturing Digital Signage minimizes the time it takes to transmit information. Downstream stations are instantly informed of a visual signal when an upstream cell starts the next job. In the event that quality identifies a non-conformance, the containment actions appear on the screen of the concerned line. Outcome: reduced stops, quicker changeovers, closer to takt.

Digital Signage for Manufacturing and Industrial Workflows

- Procurement & Stores: Dock-to-stock timers, delivery ETAs, kitting queues.

- Production: SOP videos, torque specs, tool offsets, and Andon escalation paths.

- Maintenance: MTTR/MTBF dashboards, late PMs, and predictive work orders.

- Logistics: Dock door assignments, milk-run route assignments, and forklift traffic warnings.

In all workflows, Manufacturing Data Display transforms complicated streams into glanceable, actionable displays.

How Manufacturing Data Displays Improve Decisions

Value-stream managers and supervisors do not have to search for answers; they are displayed online-side boards in OEE trend lines, first-pass yield, scrap Pareto, and changeover drift. This is the case when the story is on the screen, how, when, and where a cell underperforms. That transparency reduces the root-cause cycles and compresses control plans.

Best Digital Signage in Manufacturing: Features That Matter

Scalability Without Friction

Best Digital Signage in Manufacturing goes up to 500 screens, across shifts, buildings, and countries, and you do not have to rewrite your playbook. Add lines, not complexity.

Custom Content Scheduling

Various shifts, lines, and roles require different views. The Right Manufacturing Digital Signage plans by cell, time window, language, and compliance cycle, and rotates what each team requires next automatically.

Analytics You Will Actually Use

What slides will be ignored? When are ANDON calls highest? Plantwide analytics tell what needs to be fixed in the process and on the screen.

The Right Manufacturing Digital Signage by Facility Size

Small-Scale Facilities

Start lean: a few Manufacturing Data Display boards to show KPIs, safety, and Andon. Select cloud delivery and templates to go live in days, not months.

Medium to Large Plants

Standardize themes and data connections and roll out by value stream. Production control rooms use video walls, and cell-level screens use SOPs and quality gates.

Multi-Location Operations

De-localize content; de-localize governance. Global KPIs and policies are published at the corporate level, whereas shifts, languages, and line-specific visuals are customized at the plant level, all on the same platform.

Safety, Quality, and Compliance—On Autopilot

Digital Signage in Manufacturing can rotate OSHA topics, PPE reminders, Gemba prompts, and audit checklists on a cadence. In regulated settings, time-stamped displays and archived playlists assist in demonstrating due diligence.

Recognition that Moves the Needle

Walls become morale engines with real-time shout-outs of kaizen wins, zero-defect days, perfect attendance, and safety streaks. Multilingual layouts make sure that all teammates feel represented in the story.

Slash Downtime with Visual Alerts

When a sensor crosses the threshold line, side screens flash, showing cause, location, parts, and first-response steps. Connect the tie manufacturing digital signage software to CMMS so that a QR on the screen opens the work order. Any minute saved eliminates scrap and recovers takt.

IoT + AI: From Displays to Digital Nerve System

Attach vibration, temperature, and energy sensors to forecast breakdowns and enlist preventative measures. Allow AI to scour Manufacturing Data and Display trends to suggest staffing adjustments, ideal changeover windows, or recipe settings. This is the edge of Digital Signage in Manufacturing and Industrial performance.

Implementation Without the Headaches

It is difficult to change, so reduce friction. Launch a value stream, demonstrate ROI, then roll out. Train supervisors on the hygiene of content using vendor training. Security-segment networks, zone-tag players, and establish a cadence on content reviews. This playbook will be designed by the Right Manufacturing Digital Signage vendor.

What’s Next for Digital Signage in Manufacturing?

Predictive Maintenance Integration

AI identifies risk and nudges just-in-time PM reminders to the closest screen–not after an event, but before.

Augmented Reality Overlays

AR headsets and tablets match on-screen instructions to the actual asset to have quicker setups and fewer errors.

Production Insights AI-Driven

OEE, quality, and staffing are digested by algorithms, which suggest adjustments and post suggestions to Manufacturing Data Display boards in plain language.

Turn Every Screen into a Supervisor

If your people can see it, they can fix it. Install Manufacturing Digital Signage in the places where the work is done, integrate it with your data, and allow Digital Signage for Manufacturing to deliver safer shifts, faster cycles, and tighter quality. Select the Right Manufacturing Digital Signage solution that is right for you, wire your Manufacturing Data Displays, and provide every team with the live insight they require, at a glance, in real time.

FAQs on Digital Signage for Manufacturing

Q1. How does Manufacturing Digital Signage improve safety?

With the issuance of instant hazard alerts, PPE reminders, evacuation maps, and near-miss notices plant-wide, available, multilingual, and time-stamped.

Q2. Can it integrate with our ERP/MES and CMMS?

Yes. Leader digital signage software can be connected to ERP/MES to get orders and status, and CMMS to get PMs and work orders.

Q3. What defines the Best Digital Signage in Manufacturing?

Scalability, durable hardware, low-latency data integrations, per-user scheduling, multilingual, and actionable analytics.

Q4. We’re a small operation—does this still make sense?

Absolutely. Begin KPIs + safety + Andon on several screens. With benefits accruing, expand cells, shifts, and sites of a like platform.

Q5. How is the Right Manufacturing Signage secured?

SSO, role-based access controls, network segregation, hardened devices, and data at rest/in transit encryption.

Q6. What’s the role of Manufacturing Data Display in daily huddles?

It grounds tier meetings on live KPIs, Pareto charts, and action trackers, no printouts, no outdated numbers.

Q7. How fast can we launch?

Templates and cloud delivery enable a targeted pilot to be live in days; whole plant rollouts are usually implemented via a phased playbook.